Product Category

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu'an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

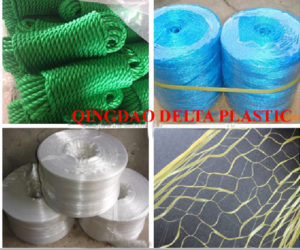

Zipper yarn, rope yarn , fish net, agriculture yarn making machine

Zipper yarn, rope yarn , fish net, agriculture yarn making machine

this machine use to produce the following products

Machine introduction:

1. Extruder

(1) Screw A diameter: 70mm; Rotation speed: 0~80rpm.

(2) Screw B diameter: 50; Rotation speed: 0~80rpm.

(3) L:D: 30:1; material of screw: 38CrMoALA ;

The screw structure is special designed for PA chips.

(4) RKC Pressure automatic feedback system can adjust the screw speed automatically.

(5) Screw heater: Cast aluminums heating rings with stainless steel insulation layer.

(6) Metering pump: 2 sets, rotation speed 0-45rpm.

(7) Electrical heating spinneret device: 1 set

(8) Heater: Electric heating ring to ensure the temperature stabilization.

2. Cooling water tank: 2 sets

(1) The tank is made by stainless steel 304.

(2) The height of tank is horizontal pushing structure is conveniently to disassembly the spinneret.

(3) Air chiller: 1 set

3, The first seven roller stretching unit

(1) Seven variable diameter rollers, material: steel pipe with hard chrome plating.

(2) Steel cabinet with accurately grind gear makes the roller run smoothly.

(3) Reducer is from Jiangsu Guomao Reducer Co., Ltd.

(4) Built-out oil lubrication system which makes the gears run steady.

(5) Equip 1 pressing roller.

4,. Overflow type hot water tank: 1 set

(1) Tank size: 4000mm

(2) Heating power: 45KW in 2 zones. Electric heating pipe is in the tank.

(3) The tank is made by SS 304 with insulating layer.

(4) Water removal device: 2 sets with suction.

5,. The second seven roller stretching unit

(1) Seven variable diameter rollers, material: steel pipe with hard chrome plating.

(2) Steel cabinet with accurately grind gear makes the roller run smoothly.

(3) Reducer is from Jiangsu Guomao Reducer Co., Ltd.

(4) Equip 1 pressing roller.

6,Hot blast oven for stretching.

(1) Oven length: 4000mm

(2) Heating power: 22.5kw, electric heating.

The temperature controlled by solid relay.

7. Seven roller stretching unit C, with brake resistor

(1) Seven variable diameter rollers made by steel pipe with hard chrome plating.

(2) Steel structure box with accurately grind gear makes the rollers run smoothly.

(3) Built-in oil lubrication system which makes the gears runs steady.

(4) Equip 1 pressing roller.

8,. Single layers hot blast annealing oven: 1 set

(1) Fan power: 2.2KW×2 sets.

(2) Heating power: 22.5KW

(3) Special design of hot air channel which make the temperature evenly.

9, The Fourth seven roller stretching unit

(1) Seven variable diameter rollers, material: steel pipe with hard chrome plating.

(2) Steel cabinet with accurately grind gear makes the roller run smoothly.

(3) Reducer is from Jiangsu Guomao Reducer Co., Ltd.

(4) Equip 1 pressing roller.

10, Spindle winder: 12 spindles

(1) Spool and bobbin are as sample.

(2) The frame transmission is frequency control, driving motor: 2.2kw

(3) The frame transmit by gear rack

(4) Winding motor: 15KG

11,. Electrical control system: 1 set

12, Overall size: 40000×2500×2000mm

13,Installation power: 180kw

machine pictures made by our factory