Product Category

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu'an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

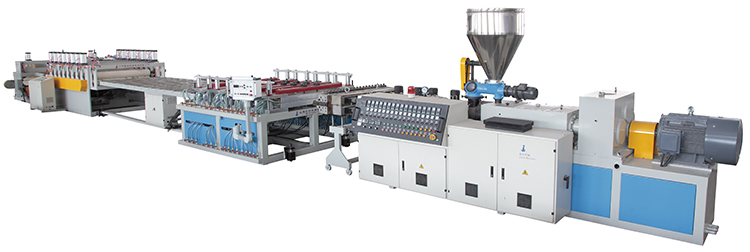

PVC WPC foam board produce machine

PVC WPC foam board produce machine

What's the products machine can produce :

1. PVC foam board with single layer

2. PVC foam board with hard skin--''celuca board called''

3. PVC board with colorful surface film

4. WPC foam board

what's the features of PVC WPC foam board

Advertisement: Such as screen printing, computer lettering, ad board, etc.

Industry: cabinet board, chemical industry antisepticizing project, thermoforming for refrigerator, for temperature keeping for environment protection, etc.

Transportation: Such as steamship, aeroplane, carriage, train compartment, roof shed, case core layer, inner upholster, etc.

Advantages

It is widely used in home-decoration, like wall board, windowsill board, door board. It can also be used for packing and plates for logistics.

1.Strong and durable; Lightweight and easy to install; Not easy to scratch;

2.Will not rot, warp, delaminate, cup or twist;

3.Resistant to weather, shock and abrasion;

4.Salt water corrosion resistant;

5.Impervious to salts, insects and many chemicals, including some acids;

6.Doesn't mold; Can be worked just like wood;

7.Non-toxic; 100% recyclable; Fire-retardant (self-extinguishing);

8.Easy to clean; Virtually maintenance free;

Machine whole features:

1. PVC/WPC foam sheet/board extrusion line consist of conical twin screw extruder , mould , calibration forming unit , conveyor cooling rollers , side cutting , haul off , cutting unit , conveyor unit , auto length calculator and storage table . the

whole line has the advantages of reasonable structure and high performance . frequency convertor is adopted for the extruder for electricity saving .

2. Screw inside adopt auto temperature controlling , screw and barrel adopt for special designed super –conical structure and the material adopt 38CrMoAiA. Extruding capacity increase 30% power save can be 20-30%. Long using life, high capacity and stable working as well as supper plasticizing are the main characters of the line. .

3. As an pioneer of PVC foam board extrusion technology, we have exported our production lines many countries customers, withour help of installation and good service ,our clients are producing best quality PVC foam board in local market

4. PVC celuka foam machinery is used to produce rigid PVC foam board used for cabinet, furniture, decoration and so on. the size of PVC foam board: width can be 900*2050, thickness can be :3-20mm

5. multiple use of the machine: the machine can use PVC raw material to make PVC foam board, also can use WPC material to produce wood plastic foam board.

6. we have serious and high level engineer teams, we don’t make cheap and weak machine. we only make high quality machine, each of our machine are our representative products. We want to win you by our quality and service .

What's our special:

1. long time experience on the board machine study and research