Product Category

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

Menu

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu'an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

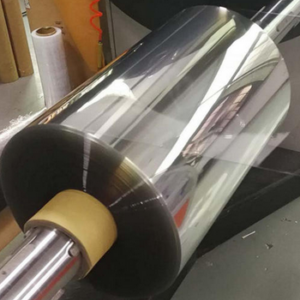

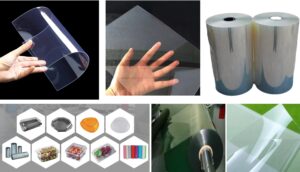

PET/PP/PS/PETG/APET thermal-forming packing sheet extrusion line

Application : use for packing food, medicine, electronics , toys, chemicals, stationery, file bags, file folder, clear/hand bags, printings.

Type : single or multi layers

Extruder : single screw/twin screw

Machine general introduction:

1. Single screw production line for PET sheet: single screw extrusion production line for APET, PETG and CPET sheet is the most mature project with the most stable production at present. Generally, single extruder production line or twin-extruder production line is adopted and the latest technology to increase the general efficiency by 30%.

2. PET sheet single screw exhaust production line: this machine only needs to crystallize PET, and does not need to dry. Its advantages: low energy consumption, simple process, convenient equipment maintenance, and can ensure the blister 18CM deep cup.

3. The PET sheet twin-screw exhaust line (free from dry and crystallization) : It is launched PET sheet twin-screw exhaust line without drying and crystallization which has the advantages of low energy consumption, high efficiency.This machine is our continuous improvement upgraded products , and its central vacuum system has been upgraded. The original roots - water ring pump group upgrades to roots - rotary vane pump, which can make the vacuum degree reach 10 pa, or less. Meanwhile by using PET special alloy steel thin-wall roller unit can increase the cooling efficiency, so as to increase output, improve product toughness and transparency. we are independently programmed operating system ensures that the device is user-friendly and easy to operate.

2. PET sheet single screw exhaust production line: this machine only needs to crystallize PET, and does not need to dry. Its advantages: low energy consumption, simple process, convenient equipment maintenance, and can ensure the blister 18CM deep cup.

3. The PET sheet twin-screw exhaust line (free from dry and crystallization) : It is launched PET sheet twin-screw exhaust line without drying and crystallization which has the advantages of low energy consumption, high efficiency.This machine is our continuous improvement upgraded products , and its central vacuum system has been upgraded. The original roots - water ring pump group upgrades to roots - rotary vane pump, which can make the vacuum degree reach 10 pa, or less. Meanwhile by using PET special alloy steel thin-wall roller unit can increase the cooling efficiency, so as to increase output, improve product toughness and transparency. we are independently programmed operating system ensures that the device is user-friendly and easy to operate.

Raw material can use granules, also can use flakes.

Raw material pre-treating system, ensure produce out high quality products.

Three calenders oil heating control temperature