Product Category

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

- PP PET packing strap yarn reinforce flexible strap produce machine

- vacuum cleaner hose and pool suction hose production line

- PET PP PBT PVC NYLON broom / wigs /eyeslash /grass / woven yarn produce machine

- PP PE PVC PU TPE flexible & yarn/wrie reinforcement hose produce machine

- Water irrigation pipe/tape produce machine

- HDPE PP PVC Single wall and Double wall corrugation pipe machine

- PVC/PE/TPU/NBR agriculture layflat hose/mining layflat hose machine /fire hose machine

- PP PE PVC water/gas pipe & COD carbon black spiral pipe produce machine

- PET PP PVC EVA filmm/sheet/board produce machine

- PVC PP PE PMMA plastic profile products produce machine

- Waste plastic recycle and granulator machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu'an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

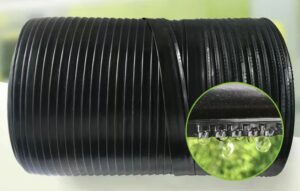

Labyrinth type irrigation tape produce machine

Products introduction :

The maze style drip irrigation tape products produced by this equipment are widely used in farmland and greenhouse planting, especially suitable for arid and semi-arid areas, and are patented products for water-saving and energy-saving irrigation.

Product features:

1. Maze channel forming and droplet hole one-time vacuum integral hot pressing forming, with high manufacturing accuracy;

2. Possess certain turbulent flow performance;

3. Uniform watering, small manufacturing deviation, and good anti clogging performance;

4. Optimize the material formula, corrosion resistance and aging resistance;

5. Different specifications of products can be produced according to user needs.

Characteristics of maze drip irrigation belt production equipment: 1. Using different or equivalent models of plastic extruders for simultaneous extrusion, and adopting variable frequency speed control to control the extrusion amount, to ensure stable and reliable operation of the production process, flexible adjustment, and reduce energy consumption. 2. The extruder screw and barrel are forged, quenched and tempered, and nitrided with 38CrMoAlA. The surface of the screw is then sprayed with hard double alloy to enhance its hardness and extend its service life. At the same time, the screw structure adopts a new type of structure, which is particularly suitable for PE recycled materials and has better plasticizing effect. 3. The forming die of double-layer composite drip irrigation tape adopts double-layer co extrusion hot runner center spiral feeding, pre cooled by cast aluminum air ring, and measured by far-infrared diameter measuring device (with built-in air pump, no external air source required) to ensure high strength and uniform thickness of the film tube. 4. Drip irrigation tape is formed using a separate vacuum forming device, ultimately meeting the standard specifications for drip irrigation tape. 5. After forming and air cooling, it enters the stainless steel water tank for circulating and shaping water cooling at the same time. 6. Drip irrigation belt traction adopts roller type traction and variable frequency speed regulation, which facilitates better and timely adjustment of production line operation. 7. The coiler adopts a three station center tension winding and is equipped with a far-infrared electronic counting device to ensure the accuracy of meter counting. At the same time, it is equipped with an automatic alarm device. When the set length is reached, it will automatically alarm and change the coil. 8. The entire production equipment adopts intelligent digital electrical control, which is easy to operate.

Our machine advantages :

high precision processing for each parts. latest and advanced technology in the key points of the machine .

easy operation , friendly to enviroment , energy saving .

according to different customers need, design and make different stage machine to meet different market .