产品分类

联系我们

地址:山东省青岛市胶州市阜安工业园滨州路128号乙

联系人:孙彩云

电话:13969867578

座机:0532-82291786

传真:0532-82291786

微信二维码:

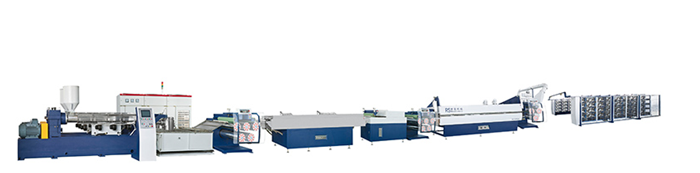

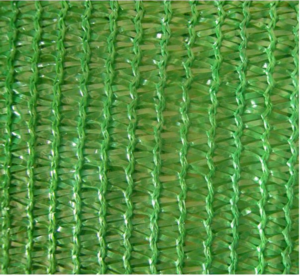

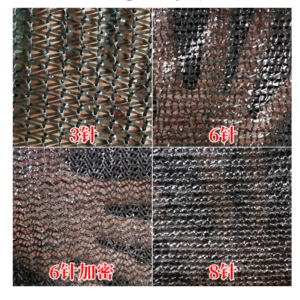

遮阳网、蔬菜袋设备

遮阳网、蔬菜袋设备

本机适用于生产扁纱,可用于生产遮阳伞、蔬菜袋、水泥袋、纤维绳等 .

本机采用PP或HDPE材料,通过材料加热和加热的生产程序,生产PP编织袋用胶带;挤出、将薄膜拆分成胶带、胶带拉伸和;用卷绕机在筒子上成型并卷绕胶带,然后将带胶带的筒子放在圆织机上织造。本机可使用各种材料,如100%再生材料、粉末材料或颗粒材料。其螺杆、汽缸等重要部件采用特殊合金钢.

| 1.Extruder Part: | |||||

| ITEM | Technical Parameter | Main parts introduce | |||

| Dia of Screw | 70mm | Raw material:PP/PE

Film size: 2.5mm 1.Frequency conversion control speed. 2. Hardtooth surface gear motor:guomaoguotai. 3. Screw and barrel surface gear motor:Jianghainkewei. 4. With automatic feeding machine. 5.Heating method of die head:electric heating 6. Single long-term filter: Φ100*420mm (L), with pressure table |

|||

| Ratio of L/D | 30:1 | ||||

| Driving Power | 18.5kw,with frequency | ||||

| Capacity of Extruder | 25kg/h-50kg/h | ||||

| Dia of Die | 600mm | ||||

| Heating power | 24kw | ||||

| Automatic feeder | 1set | ||||

| 2. Cooling Bath | |||||

| ITEM | Technical Parameter | 1.Side –push model : with 404 stainless steel

2.plat under support roll 3.Material of box: stainless steel 4.Material of distributing roller: stainless steel 5. cooling bath can move laterally |

|||

| Method of Cooling | water | ||||

| Dimension of Cooling Bath | 1.0*0.8*0.4m | ||||

| Film guider roller | 2 pcs | ||||

| 3. Film Lifting and Slitting Part | |||||

| ITEM | Technical Parameter | 1.Frequency conversion control speed

2.Rubber press roller with pneumatic device 3.Film blower: 370w/1 set 4.Reducer: 120-1:40 turbine reducer |

|||

| Stretch roller size | Φ155*700mm/2pcs | ||||

| Rubber press roller | Φ150*680mm/2pcs | ||||

| Driving power | 2.2kw | ||||

| Max stretch speed | 25m/min | ||||

| 4. Heating Plate No.1 (stretching): | |||||

| ITEM | Technical Parameter | 1.Material is stainless steel and with heat preservation, surface chromium plated

2. Heating method: electrical heating 3. Electrical control: Temperature Control System controls the temperature through solid-state relay; digital temperature controller; five area of quartz tube heating |

|||

| Dimension | 4000mm(L)*(600+150)mm(W)*10mm | ||||

| Heating Mode | Electric Heating | ||||

| Power: | 36kw | ||||

| 5.Stretching Roller No. 1 | |||||

| ITEM | Technical Parameter | 1.Frequency conversion control speed

2. Steel structure of box, chain transmission, running balance. 3.material of distributing roller: stainless steel 4.reducer: ZLY125-1:8 |

|||

| Roller Size | 295mm(D)*700mm(L) | ||||

| Quantity of Stretching Roller | 5pcs | ||||

| Speed | 160m/min | ||||

| Driving power | 5.5kw | ||||

| Control Mode | With chain box, frequency inverter | ||||

| 6. Heating Plate No.2 (sizing): | |||||

| ITEM | Technical Parameter | 1.Material is stainless steel and with heat preservation, surface chromium plated

2.heating method: electrical heating 3. Electrical control: Temperature Control System controls the temperature through solid-state relay; digital temperature controller; five area of quartz tube heating |

|||

| Dimension | 2500mm(L)*(600+150)mm(W)*10mm | ||||

| Heating Mode | Electric Heating | ||||

| Power: | 16kw | ||||

| 7.Stretching Roller No. 2 | |||||

| ITEM | Technical Parameter | 1.Frequency conversion control speed

2.steel structure of box, chain transmission, running balance 3.material of distributing roller: stainless steel 4. Reducer: ZLY125-1:8 |

|||

| Roller Size | 295mm(D)*700mm(L)/2 pcs

295mm(D)*750mm(L)/2 pcs |

||||

| Driving power | 4kw | ||||

| Control Mode | With chain box, frequency inverter | ||||

| 8. Waste yarn winder | |||||

| ITEM | Technical Parameter | 1. Motor: 100kg torque motor, adjustable torque

|

|||

| Winder size | Φ120×750mm | ||||

| Torque Motor | 100kg | ||||

| Winder part | |||||

| ITEM | Technical Parameter | ||||

| Heads of winder | 104 Winders | ||||

| Winder tube | Φ38mm×218mm(we can supply the metal tube) | ||||

| Winding speed | 0-280m/min | ||||

| Motor | 180W | ||||